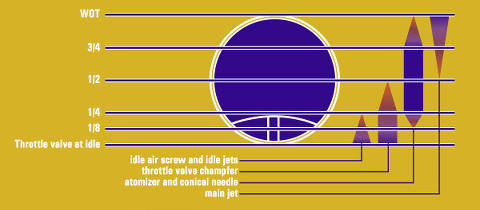

Often forgotten, idle air screw is the third most important piece to control air/ fuel mixture in a Rotax Max carburettor. It’s responsible for the transition between mixture delivery from the idle circuit and the beginning of mixture delivery from the main jet circuit. So, its main role is when the driver starts to open the throttle.

Main function

The fuel supplied by the idle circuit is mixed with a small quantity of air (controlled by the idle screw) that flows into the fuel passage (liquid) from the idle air channel. As the valve lifts, the contribution of this element decreases as far as the idle circuit is concerned, while it becomes important for the progression circuit.

Operate on the air screw, which acts as a “leaner”: by closing it we get an enrichment; by opening it a leaning. The influence of such a component, besides on the idle regularity, is detectable on the total or partial fast openings and on the returns at idle: if during the fast openings from idle we should notice some pauses, faults for lean, we have to tighten the screw in order to have an enrichment; we need to operate progressively by moving the screw of 1⁄4 turns each time. If the fault is due to too much fuel, we will have to open the air screw. It’s important to have a correct engine idle in order to have a partial and/or total good pick up without any hesitation and without shutting off during the release and return at idle condition. The adjustment of the title at idle and of the set rpm is important even to improve the cold startings (with starter on) and the warm startings (with starter off).

Adjust procedure

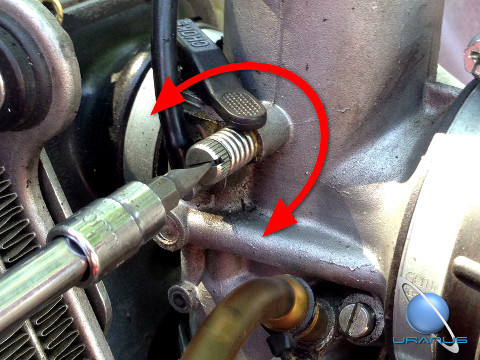

The default position of the air screw is two turns (anticlockwise) from closed position. This works for most of the occasions but we are going to describe our adjustment procedure to get better results.

First of all, engine can’t be cool for this adjustment; it’s necessary to adjust the carburettor with engine at operational temperature, between 45ºC/113ºF (minimum) and 65ºC/149ºF (best)

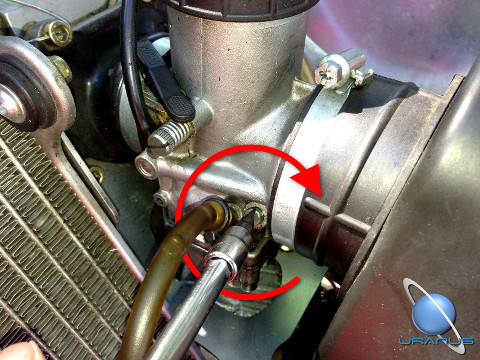

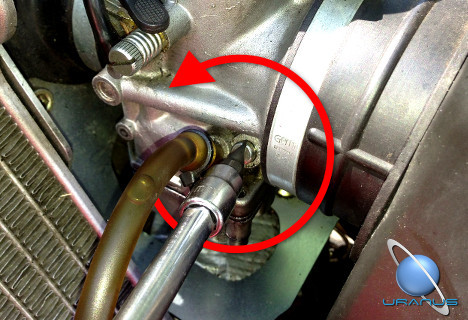

With the engine stopped, close the air screw turning it full in (not to tightly) and open it two turns. This is the default position. This is the position we need in order to adjust throttle stop screw.

Now, start the engine and adjust throttle screw to get the engine stable but as low of revs as possible (around 1.200/1.400 revs). It's easy to stall the engine a couple of times till you get the point.

Once adjusted throttle screw, stop the engine, close air screw and open it 1.5 turns. Now it’s time to listen to your engine.

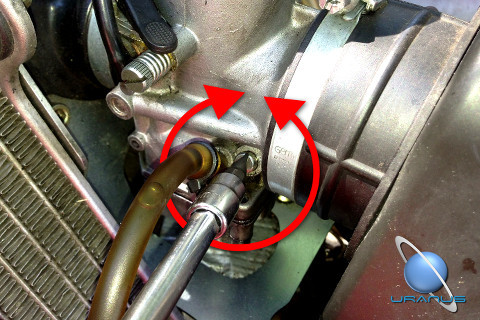

Start your engine again and very carefully open air screw till you get a smooth sound of your engine. It’s easy to get the point. Open 0.25 turns each time till the engine runs smooth, stable and with revs slightly higher that with the standard position.

Remember that the mixture is going to be leaner as you open the air. Be careful not to open too much (around 4 turns it’s my limit, but in most of the occasions my point is around 1.75).